Cold Rolled / Drawn Steel Steel Supply LP

Cold-drawn steel bars cost more than hot-rolled steel bars of the same grade, due to cost of manufacturing as well as yield loss in the manufacturing process. However, the benefits afforded to our precision machining shops are the absence of hard abrasive oxide scale, improved mechanical properties which lead to better machinability, improved.

Drawn Steel Square 4mm x 1m

Steel that is drawn passes through a series of dies to achieve a desired shape is known as drawn steel. Dies apply specified amount of pressures with the help of a machine press, and the steel starting stock typically has to be passed through the die or a series of dies more than once.

1215 Cold Drawn Steel Bar(Light rods can be provided) LION METAL

Cold drawn steel is a manufacturing process that forms extruded profiles with complex cross sections. The process begins with primary pre-treatment and descaling of the steel. The extruded steel profiles are then drawn through a forming die. This process can be repeated 3 to 4 times if necessary. The cold drawing process of hot rolled steel.

Drawn Steel Bar 8mm x 1m

Cold drawn and rolled steel. SIAT S.p.A. is a leader in the production of bright drawn wires and cold rolled flat steel from low and medium carbon wire rod. With over 40 years of experience in the drawn steel industry, it conquered an undisputed international leadership position, ranking among the first European producers.

Cold Drawn Steel Bar SAE4140 supplier in china Glorysteelwork

Cold drawn steel has similar benefits to cold rolled steel. The pressure required to make cold drawn steel results in high tensile strength and a smooth, polished finish. Like cold rolled steel, cold drawn steel doesn't change shape during processing, so the finished product has a predictable thickness and shape.

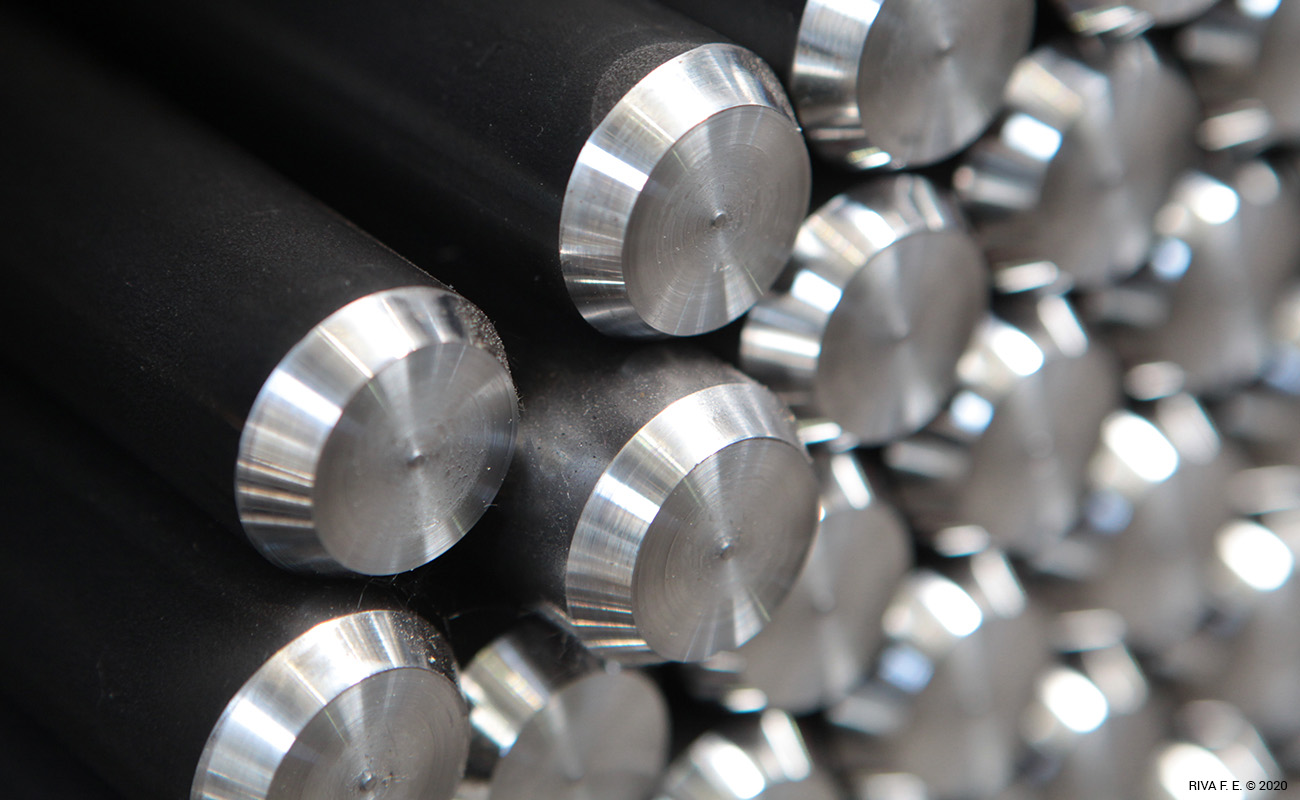

Drawn round steel bars

Cold-drawn steel is steel that has been press formed at room temperature. Cold-drawn steel is typically stronger and harder than hot-rolled steel, as the cold-drawing process work hardens the material. Cold-drawn steel is also more precise in terms of its dimensions, as the material is formed to exact specifications.

Drawn round steel bars

With unmatched strength, our cold-drawn steel is tailored for applications demanding high strength. Dimensional Precision Our cold drawing technique yields consistent dimensions and conforms to industry standards. Surface We ensure a smooth, scale free finish, reducing the need for added machining. Unwavering Straightness

DeepDrawing Steel

Cold Drawn Steel Bar. Cold drawn steel bar is created when the hot rolled material passes through a die. This results in tighter diameter tolerances and a higher strength bar product. Due to its increased precision and strength properties, this process is used to create a range of automotive parts, machined parts, and a variety of other.

Drawn Steel Diamond Mesh 500 x 250mm No. 31 Ray Grahams DIY Store

steel research international is a metallurgy journal covering process metallurgy, metal forming, materials engineering, and process control related to steelmaking. The microstructure, texture, and dislocation configuration of cold-drawn pearlitic steel wires were investigated by scanning electron microscopy (SEM), electron backscattering.

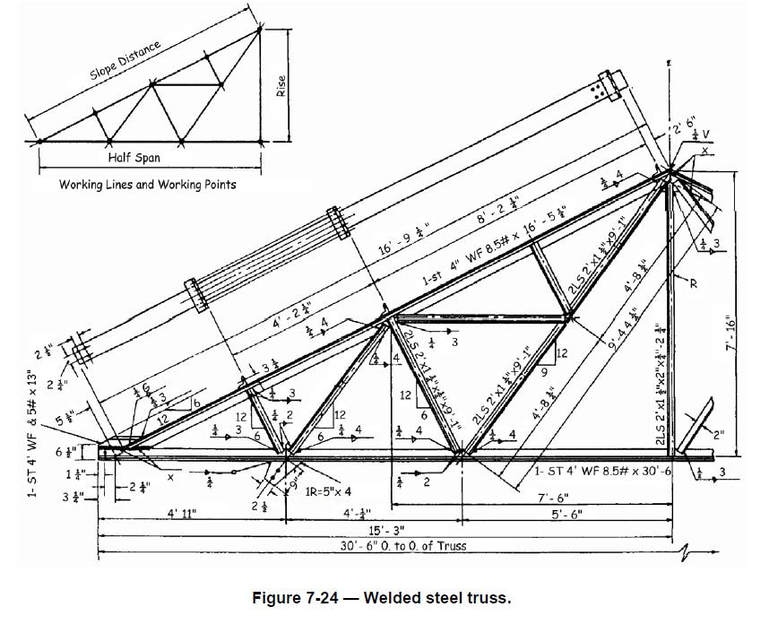

STRUCTURAL STEEL DRAWINGS ARCHITECTURE TECHNOLOGY

In a nutshell, cold drawing is the pulling of a hot rolled steel bar through a die that is slightly smaller in size. So how is cold drawn steel made? The process path consists of first shot blasting the hot rolled bar, then cold drawing it through the die, then rotary (roll) straightening, and finally cutting to length. Shot blasting:

Drawn steel, tubes and sections Valenta ZT s.r.o.

Deep drawing of steel sheets is used to form parts by a process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the steel into the desired shape without causing wrinkles or splits in the drawn part.

Как рисовать металл поэтапно 94 фото

Cold drawn steel is a refined form of steel produced through a precise manufacturing process known for enhancing mechanical properties, dimensional accuracy, and surface finish. This method involves pulling cold-rolled steel through a die at room temperature, resulting in a product that finds diverse applications across various industries. In this article, we delve into the

Standard and special cold drawn steel profiles and beams expometals

COLD DRAWN STEEL APPLICATIONS. Automobile Industry; In automobile manufacturing, the largest number of cold-drawn steels are used in trucks and large passenger cars, which are mainly used to make carriage frames, wall panels, bottom plates, body frames, bottom beams, and door and window frames. The situation for medium-sized passenger cars is.

Drawn steel, tubes and sections Valenta ZT s.r.o.

Of all "cold finished" steel bars, cold drawn bars make up the largest production in the way of sheer tonnage and usage. "Cold finished" bars consist of cold drawn , turned ground & polished, turned & ground, turned & polished, or rough turned. Cold drawn bars are used in high volume productions of machined parts as well as shafting and other applications. Their mechanical and.

ExtraDeepDrawing Steel

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter.

Deep Drawn Stainless Steel Steel Choices

Cold drawn steel bar is produced through a process that begins with either hot rolled steel coils or hot rolled straight bars from the mill. Drawing is a metalworking process which uses tensile force to stretch metal. For Cold drawn wire and bar, the starting stock is drawn through a die to reduce its diameter and increase its length..